Gaugas, ??, Exploring the Essence of Precision and Innovation

Introduction: Understanding Gaugas, ??

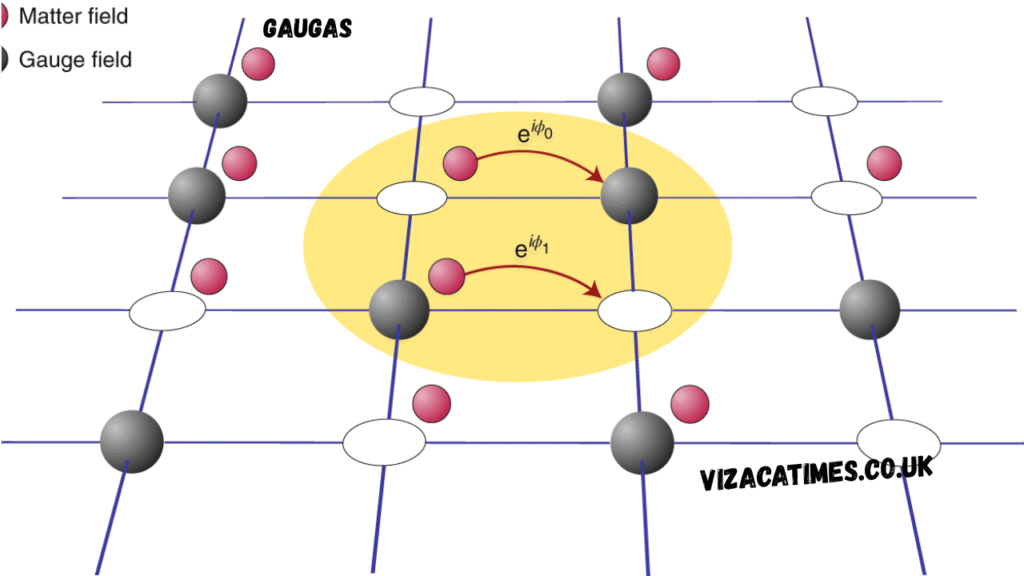

In the evolving landscape of measurement and control systems, the term “gaugas” emerges as a symbol of precision, reliability, and adaptability. While some may initially question “gaugas??”, it is essential to understand that gaugas represents a class of gauges and systems dedicated to pressure, temperature, and flow measurement across multiple industrial applications. Whether you are in manufacturing, automotive, oil and gas, or laboratory environments, understanding gaugas can streamline your workflow, enhance safety, and improve operational excellence.

This comprehensive article will help you explore what gaugas is, its applications, its significance in different sectors, and how gaugas aligns with modern technological demands while addressing the question “gaugas??” with clear, practical insights.

What is Gaugas, ??, and Why It Matter

Gaugas, ??, in its essence, refers to advanced gauge systems capable of accurate monitoring and measurement in critical conditions. The term “gaugas??” often arises when professionals look for robust and consistent tools to manage the delicate balance between efficiency and safety.

Key points about gaugas:

- Precision: Gaugas provides accurate readings, reducing the chances of error in high-stakes environments.

- Durability: Built to withstand harsh environments, gaugas tools maintain integrity under extreme pressure and temperature.

- Versatility: From laboratories to heavy industrial sites, gaugas can adapt to varied requirements.

- Ease of Integration: Modern gaugas systems integrate seamlessly with digital monitoring systems.

This makes gaugas a crucial element for engineers, technicians, and industry experts seeking dependable measurement solutions.

The Role of Gaugas in Industrial Applications

When exploring “gaugas??”, it is crucial to examine its widespread industrial applications. In many sectors, including oil and gas, pharmaceuticals, chemical processing, and food manufacturing, gaugas devices ensure precise control of environmental conditions critical for safety and compliance.

1. Pressure Measurement

Gaugas instruments excel in monitoring pressure in pipelines, ensuring that processes remain within safe operational parameters. Over-pressurization can lead to hazardous leaks or system failures; thus, using gaugas enhances safety and efficiency.

2. Temperature Monitoring

Temperature control is pivotal in chemical processing and food manufacturing. Gaugas systems ensure accurate temperature tracking, preventing spoilage or unsafe chemical reactions.

3. Flow Control

Gaugas plays a role in ensuring correct flow rates in processes requiring consistent delivery of fluids or gases, reducing material waste and maintaining production quality.

Gaugas, ??, and the Question of Reliability

The phrase “gaugas??” often implies concerns about whether gaugas systems can truly deliver under demanding conditions. The reliability of gaugas is demonstrated through:

- Calibration Stability: Gaugas systems require minimal recalibration, reducing downtime.

- Data Accuracy: Advanced sensors in gaugas devices maintain high accuracy.

- Resilience: Gaugas systems resist corrosion and mechanical damage, even in aggressive environments.

Many industries transitioning toward smart manufacturing rely on gaugas systems for continuous monitoring and data logging, reducing manual oversight while increasing productivity.

Benefits of Using Gaugas in Modern Workflows

The application of gaugas systems offers numerous benefits across industries:

- Enhanced Safety: Prevents system failures by providing real-time monitoring.

- Regulatory Compliance: Ensures that environmental and safety standards are met.

- Efficiency: Reduces material and energy wastage through precise control.

- Operational Consistency: Minimizes the chances of human error by providing reliable automated monitoring.

These advantages make gaugas indispensable for companies striving for operational excellence while maintaining safety standards.

Gaugas, ??, in the Age of Digital Transformation

As industries embrace IoT (Internet of Things) and Industry 4.0, gaugas systems play an essential role in facilitating this transition. Gaugas devices, when equipped with smart sensors, allow remote monitoring and predictive maintenance. Data from gaugas systems can be integrated with centralized management software, enabling engineers to receive instant alerts and actionable insights for maintenance scheduling.

Smart gaugas systems provide:

- Remote configuration and monitoring.

- Predictive diagnostics to prevent failures.

- Data integration with analytics platforms.

This digital evolution aligns with sustainability initiatives, reducing energy consumption and unnecessary emissions by ensuring that processes are tightly controlled and monitored.

Addressing Challenges: Gaugas, ??, in Harsh Environments

Industries such as oil and gas and chemical processing often operate in environments with extreme pressures and temperatures, making measurement tools prone to failure. Gaugas addresses these challenges by:

- Using corrosion-resistant materials for prolonged durability.

- Employing high-precision sensors that function accurately despite environmental fluctuations.

- Designing sealed units to prevent ingress of dust, moisture, and corrosive elements.

These features enable gaugas to remain operational in harsh environments, making them a trusted solution for high-risk industries.

Maintenance and Calibration: Keeping Gaugas EffectiveFuture Trends: The Evolving World of Gaugas, ??

Looking ahead, gaugas will continue to evolve in line with technological advancements:

- Integration with AI: Leveraging machine learning for predictive maintenance and anomaly detection using gaugas data.

- Sustainable Design: Development of gaugas devices using eco-friendly materials and lower energy consumption.

- Wireless Connectivity: Expansion of wireless gaugas systems for ease of installation and reduced infrastructure complexity.

As industries become increasingly data-driven, gaugas will remain a cornerstone of measurement, control, and safety in industrial workflows.

Conclusion: Why Gaugas, ??, Matters for Your Operations

To conclude, gaugas, ??, is not just a question but a pathway to operational excellence, precision, and safety in diverse industries. From accurate pressure and temperature measurements to seamless integration with digital systems, gaugas offers solutions that enhance reliability and efficiency in your workflows.

Organizations focusing on high-performance and safety-critical operations should consider investing in gaugas systems to future-proof their measurement and monitoring frameworks while aligning with global standards.

By understanding the applications, advantages, and evolving trends of gaugas, you position yourself at the forefront of precision engineering and operational reliability.

Also Read : Exploring libyh, ?? – Understanding Its Depth and Possibilities