k25lp throttle control, ?? – Understanding Precision, Performance, and Applications

Introduction to k25lp throttle control, ??

The k25lp throttle control, ?? stands as a critical component in various industrial and high-performance systems requiring precise regulation of throttle response and engine performance. Whether applied within aviation maintenance, high-performance motorsport environments, or advanced machinery, understanding the k25lp throttle control, ?? allows operators and technicians to optimize performance, efficiency, and safety.

This guide will help you explore what the k25lp throttle control, ?? is, how it functions, its key benefits, maintenance considerations, and its applications in modern systems.

What Is the k25lp throttle control, ??

The k25lp throttle control, ?? refers to a specific throttle regulation module designed to control and modulate the power output of engines or machinery precisely. The designation “k25lp” often indicates a model series compatible with various engine configurations where linear precision, responsiveness, and low-pressure (lp) operational handling are essential.

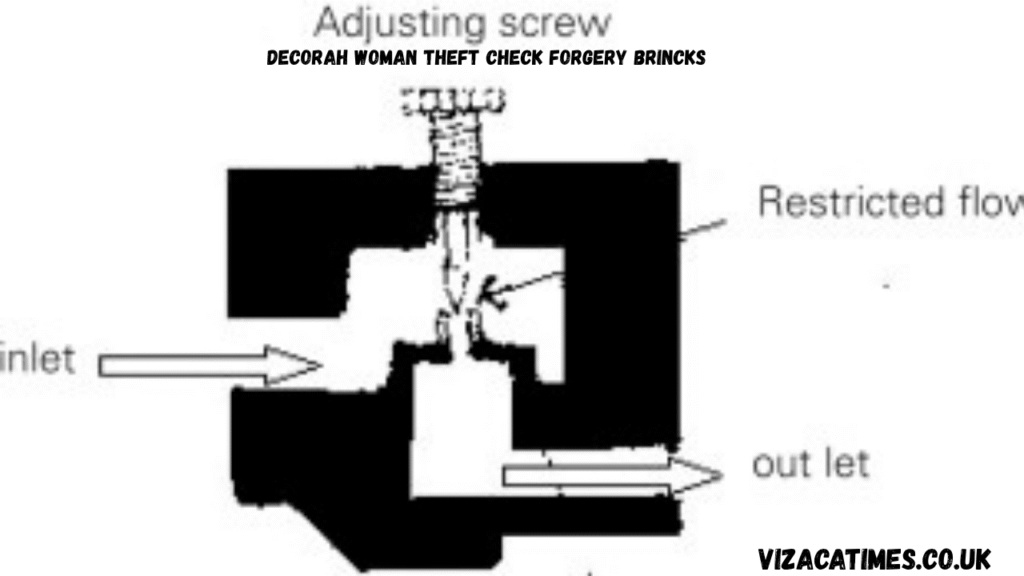

Throttle controls like the k25lp throttle control, ?? typically include:

- Throttle position sensors for precise monitoring.

- Actuation mechanisms (cable or electronic drive-by-wire systems).

- Feedback systems to ensure consistent power delivery under varying loads.

This control system is engineered to allow users to adjust throttle input smoothly while minimizing delays and inconsistencies.

The Core Functionality of k25lp throttle control, ??

At the heart of the k25lp throttle control, ?? lies its ability to convert user input into controlled mechanical or electronic output that adjusts fuel delivery or airflow, depending on the application. It often integrates:

- Electronic Control Units (ECUs) for processing input data.

- Actuators to physically adjust throttle plates or control valves.

- Feedback Loops that correct deviations from desired engine parameters.

- Safety and Fail-Safe Modes to prevent overspeed or under-throttle conditions.

By ensuring that the engine or system responds precisely to operator inputs, the k25lp throttle control, ?? helps maintain operational stability even in demanding scenarios.

Applications of k25lp throttle control, ??

The k25lp throttle control, ?? finds its place in several industries, including:

- Aviation: Ensuring smooth throttle transitions during takeoff, cruise, and landing.

- Motorsports: Allowing fine-tuning of throttle response for competitive advantage.

- Industrial Generators: Regulating engine load during varying demand cycles.

- Marine Engines: Providing consistent throttle management under variable water resistance.

- Heavy Machinery: Enhancing operator control in loaders, excavators, and specialized vehicles.

Each application benefits from the k25lp throttle control, ?? due to its low-pressure, precision-driven design, ensuring consistent performance and reliability under stress.

Benefits of k25lp throttle control, ?

Integrating a k25lp throttle control, ?? within your system offers several operational and maintenance benefits:

- Precision Control: Facilitates smoother operation with fine adjustments.

- Improved Fuel Efficiency: By modulating throttle accurately, fuel wastage can be reduced.

- Enhanced Safety: Prevents abrupt engine behavior during critical operations.

- Reduced Wear and Tear: Smooth throttle transitions minimize mechanical stress on engine components.

- Customization Options: Allows tuning of throttle curves based on specific operational requirements.

These advantages make the k25lp throttle control, ?? a preferred solution where precision and reliability cannot be compromised.

Maintenance Considerations for k25lp throttle control, ??

To maintain the k25lp throttle control, ?? in optimal working condition, consider the following practices:

- Routine Inspection: Check for wear on mechanical linkages and actuator components.

- Calibration Checks: Periodically ensure that the control’s feedback system aligns with actual throttle position.

- Cleaning: Prevent dust and debris accumulation on sensors and moving parts.

- Electrical Integrity: For electronically managed systems, inspect wiring and connectors for corrosion or damage.

- Lubrication: If applicable, maintain lubrication on mechanical components to ensure smooth movement.

Consistent maintenance of the k25lp throttle control, ?? prevents malfunctions that could lead to performance inconsistencies or safety hazards during critical operations.

Challenges in Implementing k25lp throttle control, ??

While the k25lp throttle control, ?? is robust, implementing it within systems may pose challenges such as:

- Compatibility: Ensuring the control system integrates with existing engine management systems.

- Calibration Complexity: Precision calibration may require specialized equipment and trained personnel.

- Environmental Factors: Exposure to moisture, temperature extremes, and vibration can affect longevity.

- Cost Factors: High-quality throttle control systems may be an upfront investment for long-term reliability.

These challenges can be managed effectively with appropriate planning and the use of manufacturer-recommended procedures.

Innovations Associated with k25lp throttle control, ??

Technological advancements are refining the k25lp throttle control, ?? with features such as:

- Drive-by-Wire Technology: Eliminates mechanical linkages for electronic control precision.

- Adaptive Throttle Mapping: Adjusts throttle response dynamically based on load and environmental conditions.

- Remote Diagnostics: Allows operators to monitor throttle performance remotely.

- Integration with Autonomous Systems: Enables seamless control within partially or fully automated machinery.

These innovations enhance the relevance of the k25lp throttle control, ?? in modern high-tech environments, ensuring operational flexibility and efficiency.

Case Example: k25lp throttle control, ?? in Aviation Ground Power Units

In aviation ground power units (GPUs), the k25lp throttle control, ?? ensures that engines delivering electrical power to aircraft maintain stable output under fluctuating demands. It manages the throttle to increase engine RPM when electrical demand rises while reducing fuel consumption during idle operations, all while maintaining safe operational thresholds.

This application highlights how k25lp throttle control, ?? can significantly improve the reliability and efficiency of ground operations in airports, leading to reduced operational costs and improved sustainability.

Why Choose k25lp throttle control, ?? for Your System?

The k25lp throttle control, ?? is not merely a throttle device but a critical system that enhances the overall performance, reliability, and safety of machinery and engines. By offering precise control under variable conditions, it allows operators to:

- Maximize efficiency.

- Ensure consistent output.

- Enhance operational safety.

- Reduce long-term maintenance costs.

For operations where precision throttle response is vital, investing in the k25lp throttle control, ?? aligns with modern best practices for system performance and safety.

Conclusion: Future of k25lp throttle control, ??

As industries evolve toward precision-driven automation and efficient operational practices, the k25lp throttle control, ?? will continue to play a significant role in various sectors. Its ability to provide fine-tuned control, adapt to modern electronic systems, and improve system efficiency ensures its continued relevance.

Whether you are operating heavy machinery, managing aviation equipment, or engineering high-performance engines, understanding and implementing the k25lp throttle control, ?? can lead to measurable benefits in your operations, aligning your systems with future-ready performance and reliability standards.

Also Read : Johann Heinrich Leonard III Baschi, ??, A Journey Through Legacy and Vision