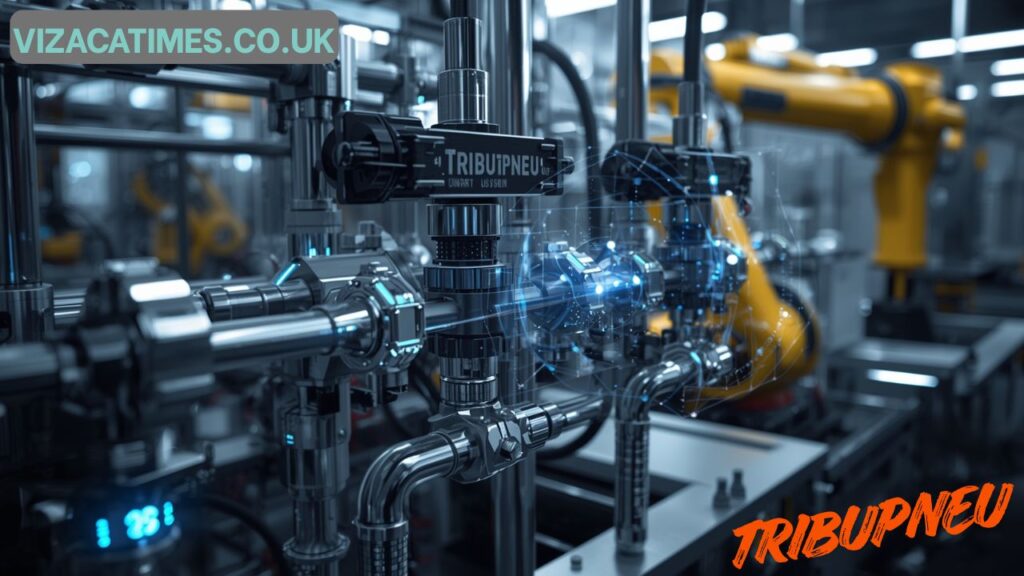

Tribupneu: The Revolutionary Smart Pneumatic System Transforming Modern Machinery

Understanding the Core Engineering Behind Tribupneu

Tribupneu represents a landmark evolution in industrial engineering, merging the fields of tribology — the science of friction, lubrication, and wear — with advanced pneumatic systems. Unlike traditional air-powered mechanisms that rely solely on compressed air and mechanical valves, tribupneu introduces a multi-layered design that integrates friction-optimized surfaces, sensor-based feedback, and intelligent flow control. As industries shift toward automation with microscopic precision, tribupneu stands out as a powerful enabler of smoother, more efficient, and more responsive mechanical movement.

At its core, tribupneu uses specialized surface coatings, micro-textured components, and low-friction materials to drastically reduce mechanical loss inside pneumatic chambers and actuators. When paired with its dynamic airflow system and pressure-balancing algorithm, tribupneu achieves motion that is cleaner, faster, and dramatically more energy efficient. This technological leap places tribupneu at the center of modern industrial innovation, making it invaluable for robotics, manufacturing, assembly lines, aerospace systems, and advanced mechanical automation.

How Tribupneu Improves Mechanical Efficiency at Every Level

The tribupneu architecture enhances performance by optimizing every stage of pneumatic motion. Traditional pneumatic cylinders often experience sticking points, resistance spikes, inconsistent airflow distribution, and wear-related decline. Tribupneu eliminates many of these issues through a design built around precision engineering.

One of its breakthroughs lies in its friction-optimized piston surfaces. These surfaces include engineered micro-grooves that allow air to circulate more evenly, preventing hotspots that could otherwise cause friction buildup. In older systems, inconsistent lubrication often leads to uneven mechanical movement. With tribupneu, however, lubrication is managed through self-distributing coatings activated by heat and pressure, keeping the entire mechanism functioning with near-zero loss.

Tribupneu also introduces positional accuracy previously reserved for servo motors and hydraulic solutions. By integrating sensor-fed feedback loops, every small adjustment in pressure is instantly corrected, resulting in near-perfect alignment between requested movement and actuator performance. This means industrial robots can pick, place, lift, and rotate with greater precision than older pneumatic systems ever allowed.

The Tribology–Pneumatic Fusion: Why Tribupneu Is Groundbreaking

Tribology has long played a role in mechanical engineering, but its direct integration into pneumatic systems is what makes tribupneu revolutionary. Most pneumatic devices rely on standardized cylinder interiors, lubricants, and seals. Tribupneu enhances these using tribological insights that restructure airflow patterns and eliminate unnecessary drag.

Micro-coatings in tribupneu systems create an ultra-smooth environment inside pneumatic chambers. These coatings continuously self-adjust by reacting to changing pressure levels, forming a dynamic interface that protects surfaces from wear. This extends the lifespan of machinery significantly while reducing maintenance costs.

Another major advantage is heat distribution. As compressed air expands and contracts, temperature changes can affect mechanical stability. Tribupneu’s tribological design minimizes these shifts, promoting thermal balance and reducing component strain. Over long cycles, this stabilization allows tribupneu-equipped machines to operate consistently without the gradual deterioration seen in traditional systems.

By fusing tribology with pneumatic engineering, tribupneu essentially redefines what air-powered motion can achieve.

The Intelligent Control System Inside Tribupneu

What sets tribupneu apart is not only its physical engineering but also its intelligent control infrastructure. Using digital flow regulators, adaptive pressure algorithms, and real-time monitoring sensors, tribupneu operates as a closed-loop performance system rather than a simple mechanical device.

Its control unit analyzes pressure demand, actuator load, environmental conditions, and movement requirements, adjusting airflow instantly. This prevents common pneumatic problems such as jerky starts, unsynchronized motion, and force overshoot. The result is motion that feels almost electric in its responsiveness — but with the cost-efficiency and simplicity of compressed air.

Machine operators benefit from unprecedented tuning capability. Tribupneu allows for programmable speed curves, custom motion profiles, and dynamic torque adjustments. Engineers can design specific movement recipes that the machine executes consistently, making tribupneu ideal for repetitive precision tasks.

In robotics, this intelligent control allows arms, grippers, and manipulators to perform highly delicate actions such as handling fragile components, assembling microelectronics, or operating in clean room conditions. Unlike hydraulics, which may risk fluid leaks, tribupneu remains clean, lightweight, and environmentally safe.

Energy Efficiency and Sustainability Advantages of Tribupneu

A major force behind tribupneu’s rise is its energy-efficient performance. Pneumatic systems are notorious for energy waste due to leakage, poor seals, and friction loss. Tribupneu addresses all three problems through friction-minimized surfaces, improved sealing technology, and air-flow recalibration.

Tribupneu-equipped machinery consumes significantly less compressed air, translating to reduced operational costs and a smaller environmental footprint. Many factories spend up to 30 percent of their energy budget on generating compressed air; tribupneu directly reduces this figure by improving air utilization.

Additionally, tribupneu reduces the need for frequent lubrication changes or chemical additives. Its self-adjusting tribology coatings require far fewer interventions, minimizing the disposal of industrial oils and lubricants.

This makes tribupneu appealing for companies transitioning to greener manufacturing models, where sustainability and cost-efficiency must go hand in hand.

Applications of Tribupneu in Robotics and Automation

Robotics represents one of the strongest application domains for tribupneu. Traditional pneumatic robots often lack fine motor control, limiting them to repetitive tasks that require minimal precision. Tribupneu overturns these assumptions by bringing smooth, precise, and highly controllable motion to robotic devices.

In collaborative robots (cobots), tribupneu makes movements safer and more fluid for interactions between humans and machines. The pressure-adaptive sensors allow cobots to instantly reduce force when needed, preventing accidental collisions or damage.

In industrial robotics, tribupneu enhances speed and accuracy, allowing for faster production cycles without sacrificing precision. Packaging, assembly, and sorting robots benefit immensely from the smoother movement and longer lifespan of tribupneu-powered actuators.

Automated guided vehicles (AGVs) and factory transport robots also gain from tribupneu due to its ability to adjust torque and movement patterns in real-time, improving both stability and efficiency.

Tribupneu in Aerospace and High-Performance Machinery

The aerospace industry increasingly requires lightweight, efficient, and reliable actuation systems. Hydraulics offer power but add significant weight and maintenance requirements. Tribupneu presents a compelling alternative.

Aircraft mechanical systems using tribupneu can perform essential functions such as flap control, hatch actuation, ventilation adjustment, and internal component handling with reduced weight and greater reliability. The tribological coatings inside tribupneu cylinders withstand extreme temperature fluctuations common in aerospace environments.

Additionally, satellites and space exploration devices benefit from tribupneu’s low-maintenance design. The absence of fluid-based hydraulic systems eliminates the risk of leaks and contamination in vacuum environments.

High-performance machinery such as CNC equipment, semiconductor fabrication systems, and laboratory automation tools also adopt tribupneu for its microscopic precision and low-latency actuation.

Industrial Benefits: Longevity, Reliability, and Reduced Maintenance

Tribupneu dramatically enhances the performance lifespan of mechanical equipment. By reducing surface wear and maintaining lubrication stability, it extends the operational lifetime of pneumatic cylinders, valves, and actuators far beyond traditional standards.

Maintenance schedules become less frequent and more predictable. Many tribupneu systems are capable of self-diagnosing wear patterns through integrated sensors. Operators receive alerts before small issues become costly repairs.

Reliability is also improved through the elimination of sudden pressure spikes and motion inconsistencies. Tribupneu’s real-time monitoring ensures smooth operation throughout long production runs, allowing factories to maintain continuous output without unexpected downtime.

The economic benefits are substantial, particularly for large-scale production facilities that rely heavily on pneumatic automation.

Tribupneu and the Evolution of Smart Manufacturing

Tribupneu plays a significant role in the broader shift toward Industry 4.0 — the integration of smart technologies, automation, and data-driven manufacturing. As factories incorporate artificial intelligence, IoT sensors, and digital-twin systems, tribupneu provides the physical foundation for the next level of mechanical intelligence.

Its real-time sensors generate data that can be analyzed using machine learning algorithms. This allows machines to self-optimize, predicting wear, adjusting performance dynamically, and adapting motion to maximize efficiency.

In smart factories, tribupneu becomes a building block of connected mechanical intelligence, enabling systems to communicate, collaborate, and react autonomously.

Future Innovations Building on Tribupneu

The future of tribupneu includes deeper integration with AI, nanotechnology, and autonomous robotics. Researchers are developing tribupneu variations capable of micro-scale movement for use in medical devices and biotechnology applications. Imagine air-powered surgical tools that can operate with the precision of robotic arms — tribupneu is paving the way.

Nanocoatings will become even more advanced, allowing tribupneu surfaces to heal micro-abrasions automatically. Energy recovery systems may soon capture pneumatic exhaust air and redirect it, improving sustainability further. And modular tribupneu components will allow manufacturers to customize systems for specific tasks with unprecedented flexibility.

As global industries expand automation demand, tribupneu will likely become a standard technology powering robotic systems, manufacturing lines, aerospace components, and smart industrial environments.

Why Tribupneu Is the Future of Pneumatic Engineering

Tribupneu stands out as a revolutionary advancement because it solves the long-standing limitations of traditional pneumatic technology. Its friction-optimized design, intelligent control features, energy efficiency, and adaptability make it ideal for modern high-precision environments.

By merging tribology and pneumatics into a single unified system, tribupneu represents one of the most promising innovations in industrial automation. With benefits extending from robotics to aerospace and from smart factories to heavy machinery, tribupneu is positioned to redefine how mechanical systems move, operate, and evolve.

As industries embrace digitization and intelligent automation, tribupneu will undoubtedly become a cornerstone of next-generation engineering.

Also Read : Exploring Klasody A Modern Approach to Digital Learning and Collaboration