What is Steelwork, ??, Exploring the Backbone of Modern Structures

Introduction to What is Steelwork

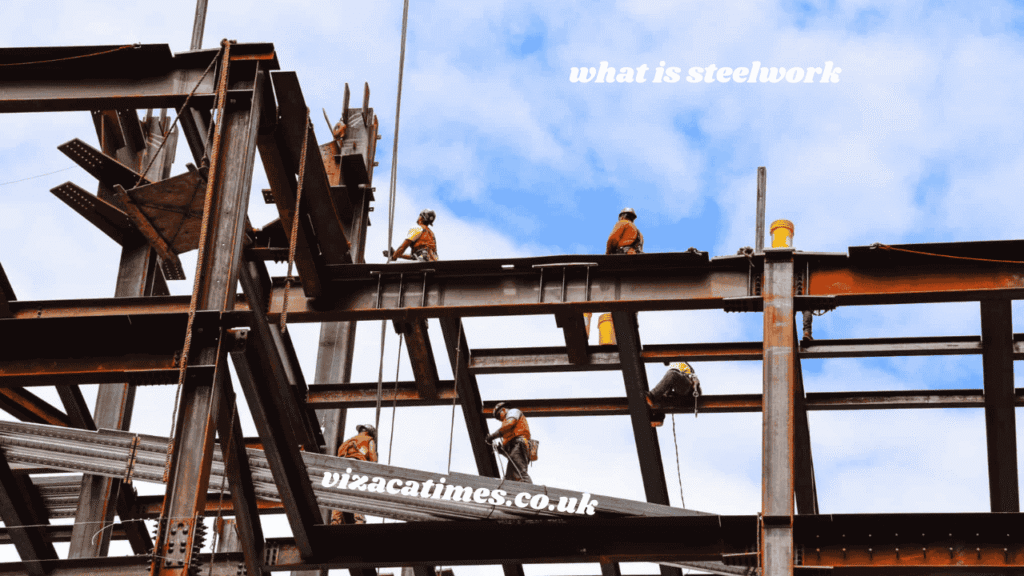

“What is steelwork” is a question often asked when discussing the essential components of modern construction, industrial manufacturing, and architectural design. At its core, steelwork refers to the design, fabrication, and installation of steel components that form the skeleton or framework of buildings, bridges, and infrastructure projects. The reason steelwork is so critical in today’s world is its strength, durability, versatility, and recyclability, making it the backbone of our urban skylines and transportation networks.

This detailed article on “what is steelwork, ??” will guide you through its definition, processes involved, types of steelwork, applications across industries, benefits, challenges, and the skills needed in the steelwork industry.

What is Steelwork: Definition and Core Concept

To understand “what is steelwork,” it is important to see steelwork as the structural aspect of steel use in construction and engineering. It involves preparing steel materials, cutting, welding, drilling, and assembling them to create frameworks that support buildings and large structures. It is not limited to large-scale projects; steelwork is also used in smaller structural supports, staircases, and even public art installations.

Steelwork typically uses beams, columns, girders, trusses, and bracing as the primary components. These components are precisely designed to handle the loads and stresses of a building while maintaining stability under various environmental conditions.

What is Steelwork in the Context of Structural Engineering

A crucial point when asking “what is steelwork” is its integration within structural engineering. Steelwork professionals collaborate with engineers to ensure that the steel framework meets the technical and safety requirements of the project. Engineers calculate the load-bearing capacity, wind resistance, and seismic considerations while steel fabricators turn these calculations into tangible structures.

Structural steelwork includes:

- Steel frame construction for skyscrapers

- Bridge girders and trusses

- Reinforced frameworks in industrial plants

- Stadium and arena frameworks

- Warehouses and factories with steel frames

This demonstrates that steelwork forms the structural skeleton of modern infrastructure.

What is Steelwork Fabrication

An integral part of understanding “what is steelwork” involves the fabrication process. Steelwork fabrication is the process of converting raw steel into usable components that fit the design requirements of a structure. The stages of steelwork fabrication include:

- Design and Drawing: CAD drawings are prepared to exact specifications.

- Cutting and Shaping: Steel sections are cut using saws, plasma cutters, or lasers.

- Drilling and Welding: Connection points are drilled, and sections are welded as required.

- Surface Treatment: Steel may be galvanized or painted for corrosion resistance.

- Quality Control: Inspections ensure that fabricated components meet project standards.

- Assembly: Components are assembled and prepared for transportation to the construction site.

The fabrication process in “what is steelwork” ensures accuracy, safety, and compliance with engineering standards before installation on-site.

Types of Steelwork

When exploring “what is steelwork,” understanding its types helps appreciate its wide-ranging applications. Key types of steelwork include:

- Structural Steelwork: For buildings, bridges, and towers requiring load-bearing frameworks.

- Architectural Steelwork: Custom-designed steel for aesthetic features like staircases, canopies, and decorative facades.

- Light Gauge Steelwork: Used in residential and light commercial buildings where lighter, flexible structures are needed.

- Heavy Steelwork: For industrial facilities, stadiums, and large-span structures where heavy-duty steel components are required.

- Pre-fabricated Steelwork: Components fabricated off-site and assembled quickly on-site to reduce construction time.

These categories highlight how “what is steelwork” extends across different scales and industries.

What is Steelwork in Modern Construction

In today’s construction industry, “what is steelwork” is directly tied to efficiency and sustainability. Steel frameworks allow for rapid construction compared to traditional concrete methods, enabling the erection of multi-story buildings within weeks rather than months. Moreover, steel is recyclable, making steelwork environmentally conscious when managed properly.

Steelwork in modern construction includes:

- Skyscrapers with steel frameworks supporting glass facades

- Modular construction where steel components are assembled into building modules

- Bridges with steel trusses and girders for long-span crossings

- Industrial plants with steel support systems for heavy machinery

- Airports and transportation hubs requiring large open spaces with steel-supported roofs

These applications showcase the versatility of steelwork in the construction of contemporary structures.

Benefits of Steelwork

To fully understand “what is steelwork,” it is essential to know its benefits:

- High Strength-to-Weight Ratio: Steel provides strength without excessive weight, making it ideal for large structures.

- Durability: Resistant to pests, weather, and decay.

- Flexibility in Design: Allows for creative architectural designs and large open spaces.

- Speed of Construction: Pre-fabricated steel components reduce on-site construction time.

- Recyclability: Steel can be recycled repeatedly without losing strength.

These benefits make steelwork a preferred choice in a variety of projects globally.

Challenges in Steelwork

While discussing “what is steelwork,” acknowledging its challenges is important for a balanced perspective:

- Corrosion: Requires protective coatings or treatments to prevent rusting.

- Fire Resistance: Steel loses strength at high temperatures and requires fireproofing methods.

- Precision Requirements: Steelwork demands high precision during fabrication and installation.

- Cost Fluctuations: Steel prices can fluctuate based on global demand and supply chains.

Overcoming these challenges requires skilled professionals, advanced equipment, and quality management in steelwork operations.

Careers in Steelwork

Understanding “what is steelwork” also involves recognizing the career opportunities it creates. Careers in steelwork include:

- Steel fabricators and welders

- Structural steel designers

- Site steelwork installers and erectors

- Quality control inspectors for steel fabrication

- Project managers for steelwork projects

These careers require a blend of technical skills, safety awareness, and teamwork, making steelwork a viable career path for those interested in construction and engineering.

Conclusion: Why Understanding What is Steelwork Matters

“What is steelwork” is more than just a technical query; it is a gateway to understanding how our cities, bridges, and essential infrastructures are built. Steelwork is the silent strength behind towering skyscrapers, reliable bridges, and resilient industrial structures. From fabrication to installation, steelwork encompasses precision, engineering excellence, and sustainability, making it a cornerstone of the built environment.

Whether you are a student exploring construction, an aspiring engineer, or simply curious about the frameworks that hold your city together, understanding “what is steelwork, ??” gives you insight into one of the most important components of modern society. It is an industry built on innovation, reliability, and the continuous pursuit of creating stronger, safer, and more sustainable structures for the world.

Also Read : Barbara Sienkiewicz, ?? – Her Life and Choices